Solidworks Pcb Open Gerber Files

Importing Gerber/DXF from PCB into SolidWorks As the design of PCB's becomes more complex, the need to do 3D modeling of a printed circuit board also becomes more important. Many PCB design tools have an interface to SolidWorks via the IDF file format - however this approach is useful mostly for components, connectors, board outline.

In this Gerber tutorial, I will teach you how to create the files you need for a 2-layer board using Cadsoft Eagle. After you have completed this tutorial you will have all the necessary files needed to send to most PCB manufacturers.

- Hello Rony, Artwork Conversion Software is a SolidWorks partner and we have been offering a translator from SolidWorks to Gerber for over 4 years.

- Something like a multi-layer sandwidth: Each Gerber conductor layer on its own Z-level in SolidWorks with a given thickness. Between each conductor layer a solid body representing the FR4. Drill holes running through the entire assembly like toothpicks holding the whole thing together. We are going to import into a SolidWorks part.

This tutorial is out of date. I have switched to KiCad, so I recommend the updated tutorial How to Create Gerber Files in KiCad.

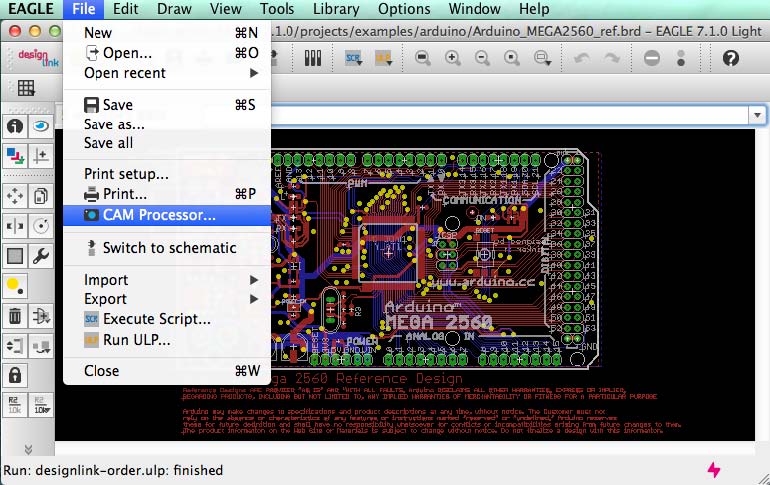

Step 1: Open the CAM Processor

In Eagle, open Board view. Click the “CAM” button or choose “File->CAM Processor”. This will open the CAM Processor tool that is used to generate the files.

Here you can define the sections you want to create files for.

But you don’t really need to understand this. Actually I have never really thought about the details of this until I was writing this article. I have just been using ready-made configurations. And that is probably what you want to do as well.

Step 2: Open a predefined job

To simplify creating Gerber files, Eagle comes with a predefined job for this. It is called gerb274x.cam.

(Note: If you want to order PCBs from Seeed Studio’s Fusion PCB service, you should instead download their own CAM-file from the bottom of their submission guidelines page. Be aware that this will give you different file names than the ones listed below in this article.)

To open it in the CAM Processor click “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and you should see a file called gerb274x.cam. Choose it and click “Open”.

You will now see five tabs in the CAM Processor. Each of these tabs will generate a Gerber file.

Step 3: Adding a second silk screen (Optional)

If you look at the tabs, you will see that you don’t have a file for silk screen bottom. For simple boards, the silk screen is usually on the top layer so that you don’t need the bottom. Some of the cheap circuit board manufacturers don’t even allow bottom silk screen.

But if you need silk screen on bottom layer as well, follow these steps:

- Click “Add”

- Change Section to something like “Silk Screen SOL”

- Change File to “%N.pls”

- Deselect all layers

- Select layers 20 “Dimension”, 22 “bPlace” and 26 “bNames”

There you go.

Step 4: Create each gerber file

Select where you want to put the Gerber files by clicking on the “File” button and choosing a folder. Do this for all the tabs.

Then click “Process Job”. This creates your Gerber files.

Step 5: Adding file for drill holes

Even though drilling is supported by the Gerber format, manufacturers usually want the Excellon file format for specifying drill holes. Luckily, Eagle also comes with a predefined job for creating a drill file.

(Note: This step is automatically done if you’re using the CAM-file from Seeed Studio that I linked to in step 2.)

Open it in the CAM Processor by clicking “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and open the file named “excellon.cam”.

Select where to put the output file by clicking on the “File” button.

Then click “Process Job” to create your Excellon file.

Step 6: Check output files

You should now have the following files:

- *.cmp (Copper, component side)

- *.drd (Drill file)

- *.dri (Drill Station Info File) – Usually not needed

- *.gpi (Photoplotter Info File) – Usually not needed

- *.plc (Silk screen, component side)

- *.pls (Silk screen, solder side)

- *.sol (Copper, solder side)

- *.stc (Solder stop mask, component side)

- *.sts (Solder stop mask, solder side)

After you have created each gerber file, you should always look at them using a Gerber viewer to make sure everything is ok.

Summary

This Gerber tutorial shows one way of creating the files you need. Even though this should be OK for many PCB manufacturers, you might find that some would want the files created in a slightly different way. If so, don’t worry, they will probably provide you with a Job file you can load directly into Eagle or at least have a good explanation on how to do it on their website.

Check out more articles on PCB design by clicking this link:

Return from Gerber File to PCB Design

Gerber files are a key piece to the puzzle for manufacturing printed circuit boards. They contain all the necessary data that a PCB manufacture will require to produce the boards to your exact specifications accurately. Advanced Circuits offers free tools like our PCB Artist Design Software simplifies the way you transfer your design files to us for fabrication. Our FreeDFM Gerber file check tool is another way Advanced Circuits makes it easier to ensure all your files are complete before placing your order.

In this post, we discuss the basics of printed circuit board Gerber files. For more detailed information about Gerber file generations and our requirements, click here. For more PCB design and manufacturing resources, visit our PCB Engineering & CAM Resources page.

What are PCB Gerber Files

A Gerber file is basically an image of a PCB. It showcases each individual layer as it appears throughout your circuit design. Gerber files represent copper layers images, solder mask, legend, and drill and route data helping to simplify the process of seeing how the circuit board should be fabricated. The Gerber files also contain attributes that provide meta-information about these images, such as whether a graphics object is and SMD pad, a via pad, a fiducial, or any other type of element.

Multiple programs have the ability to read a Gerber file format due to its simplicity, yet detailed descriptions of its contents. They additionally assist in locating potential issues and debugging of the circuit design when uploaded to our FreeDFM file check tool. When submitting a Gerber file, it is wise to send a straightforward text (.txt) file with the explanation of the requirements that may not appear in the file as a note to the PCB manufacturer.

What’s Included in PCB Gerber Files

When exporting the set of Gerber files for your PCB design, you will notice there is a set of individual files with different extensions which should be saved as a zipped folder to send over to the PCB manufacturer. These files are the following elements of your circuit board design:

How To Open Gerber Files

- Top Silkscreen

- Top Soldermask

- Top Copper

- Top Solderpaste

- Inner Copper

- Bottom Copper

- Bottom Soldermask

- Bottom Silkscreen

- Bottom Solderpaste

- NC Drill

- Non Plated Drill

- Slots

- Drawing/Other

Solidworks Pcb Open Gerber Files Download

When submitting your files for PCB fabrication, you will need to map your files (match) to the elements mentioned above. Common file name extensions are listed in the image below.